Product & Services » Waste Water Treatment Plant » Effluent Treatment Plant

Effluent treatment plant

EBR Technology provides high standard of efficiency for industries. B.O.D and C.O.D reduction will be minimum level i.e. up to 85%. We expertise in treating leachates ,dying ,leathers ,paper ,distilleries etc..,

Benefits:

Land requirement is very less compared to other effluent treatment.

Waters will be suitable for reuse.

85% removal of B.O.D and C.O.D with combination of various systems.

Applications:

Sugar

Dying

Leathers

Papers

Glass

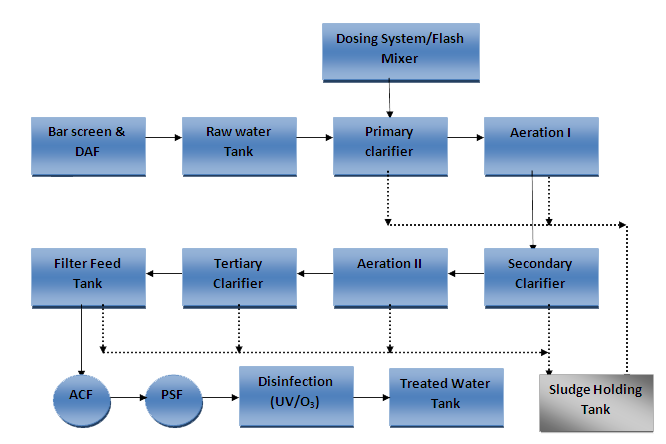

PROCESS FLOW CHART

Bar Screen

Bar screens are typically at the head works (entrance) of a wastewater treatment plant (WWTP), bar screens are used to remove large objects such as rags, plastics bottles, bricks and solids from the waste stream entering the treatment plant. Bar screens are vital to the successful operation of a plant, they reduce the damage of valves, pumps, etc., Floatables are also removed at the entrance to a treatment plant, that "float" on the surface of the water.

Dissolved Air Flotation (DAF)

Dissolved air flotation (DAF) is a water treatment process that clarifies wastewaters (or other waters) by the removal of suspended matter such as oil or solids. The removal is achieved by dissolving air in the water or wastewater under pressure and then releasing the air at atmospheric pressure in a flotation tank or basin. The released air forms tiny bubbles which adhere to the suspended matter causing the suspended matter to float to the surface of the water where it may then be removed by a skimming device.

Raw Water Collection Tank

Raw water collection tank receives the wastewater from several sources like kitchen, canteen, dining hall, bathing, flushing etc., It act as an equalization tank during peak flow of wastewater. Two submersible pumps are provided in raw water collection tank to pump the sewage to packaged unit for biological treatment.

Dosing system

The equalized wastewater will be pumped to dosing tank. Dosing chemicals into membrane treatment systems is essential for efficient and effective operation. Dosing the correct chemical at the optimum rate and in the most effective manner will ensure long-term plant performance is optimized.

Primary Clarifier (Clarifier - I)

The primary clarifier is adopted to clarify the semi treated wastewater which is present. Chemical dosing is required in effluent treatment process. An appropriate retention time and plate settlers with the baffle tray are provided for effective clarifying activity. The sludge from the clarifier is drained to the sludge holding tank when there is an excess of sludge. As the sludge settles down the supernatant from the clarifier is taken over to the Bio Reactor - I.

Bio Reactor – I

Raw water is given to Bio Reactor – I. This is the first step of biological treatment process. It receives the wastewater with the help of submersible pump. Bio Reactor – I consists of Eco Bio Blocks and diffusers. Diffuser provides aeration to the microorganism present in the block. The microorganisms present in the block start to multiply and act on the organic matter present in the wastewater. These organisms degrade the organic constituents by utilizing them as food. From the Bio reactor I, the wastewater overflows to clarifier - I (primary clarifier).

Secondary Clarifier (Clarifier - II)

The aerated water is overflowed to clarifier – II. It has the same application as clarifier - I. The solids settled effectively with the help of plate settler arrangement and they collected to sludge holding tank. Clarified water is overflowed to the Bio reactor - II.

Bio-Reactor - II

From the secondary clarifier, the wastewater overflows to the Bio Reactor – II, which consists of Eco Bio Blocks for the treatment of rest of the organic matter present in the wastewater under aerobic conditions. Diffused aeration takes place to enhance the microbial growth by using the air blower. In this chamber the entire organic matter will be degraded by the microorganism. After the treatment of wastewater, it is passed to the clarifier - III.

Tertiary Clarifier (Clarifier - III)

The aerated water is overflowed to clarifier - III from bio reactor - II. Clarifier - III has the same application as clarifier – I & clarifier - II. The solids settled effectively with the help of plate settler arrangement and they collected to sludge holding tank. Clarified water is overflowed to the filter feed tank.

Filter Feed Tank

The clarified water is passed to the filter feed tank. From here the treated water is pumped to the carbon and sand filters, where the suspended solids, colour and odour will be removed.

Filtration (Carbon & Sand Filters)

The treated water is pumped from filter feed tank to carbon and sand filters. In this chamber the suspended impurities and odor is removed. The treated water will be passed to the UV sterilizer or Ozone for disinfection process.

Disinfection

Disinfection will be done by Ultra Violet (UV) or Ozone. Disinfection of wastewater is done to prevent infectious diseases from being spread and to ensure that water is safe for human contact and the environment. UV decomposes rapidly, and therefore, it leaves no harmful residual that would need to be removed from the wastewater after treatment. Another common use for UV in wastewater treatment is odor control. Ozone is made of oxygen and reverts to pure oxygen, it vanishes without trace once it has been used. When ozone disinfects or breaks down harmful bacteria or pollutants, there are generally no by-products, unlike most disinfecting agents.The disinfected water is stored in Treated water tank.

Treated Water Tank

After completing the treatment process the final treated water stored in treated water tank and used for gardening or flushing applications. It is also safe for disposal in water bodies or discharges back to the earth. The treatment process takes place at uniform flow rate. The Plant is designed for 20 hours of operation period.

Sludge Drying Bed

Sludge is getting collected from Primary Clarifier, Secondary Clarifier and Settling tank based on the amount of sludge present in the tanks. The collected sludge should be pumped to sludge drying bed.